Transistors are the basis for electronic switching and memory devices as they exhibit extreme reliabilities with on/off ratios of 104–105, and billions of these three-terminal devices can be fabricated on single planar substrates. On the other hand, two-terminal devices coupled with a nonlinear current–voltage response can be considered as alternatives provided they have large and reliable on/off ratios and that they can be fabricated on a large scale using conventional or easily accessible methods. Here, we report that two-terminal devices consisting of discontinuous 5–10 nm thin films of graphitic sheets grown by chemical vapour deposition on either nanowires or atop planar silicon oxide exhibit enormous and sharp room-temperature bistable current–voltage behaviour possessing stable, rewritable, non-volatile and non-destructive read memories with on/off ratios of up to 107 and switching times of up to 1 μs (tested limit). A nanoelectromechanical mechanism is proposed for the unusually pronounced switching behaviour in the devices.It will be several years before memories based on these switches are available for laptops and desktops, but it's a cool thing. To my knowledge, the mechanism is not yet known, so there may be some interesting new science involved as well.

Tinkering with various electronics and software things, and a bit of math and science in general.

Monday, December 29, 2008

Graphene memory device at Rice University

Picasa images in blog posts

Here is an example of embedding a Picasa image in a Blogspot posting. I am including this to assist another blogger who is doing some interesting RepRap-related work but who's had a bit of trouble with Blogspot. To do this, I got the URL for the Picasa image by right-clicking on "View image" in Firefox so that I only had the image in the browser, and I used that in the "Add Image" thing in the "New post" top bar menu.

Here is an example of embedding a Picasa image in a Blogspot posting. I am including this to assist another blogger who is doing some interesting RepRap-related work but who's had a bit of trouble with Blogspot. To do this, I got the URL for the Picasa image by right-clicking on "View image" in Firefox so that I only had the image in the browser, and I used that in the "Add Image" thing in the "New post" top bar menu.The HTML for this post (in part) looks like this:

<a onblur="try {parent.deselectBloggerImageGracefully();} catch(e) {}" href="http://lh6.ggpht.com/_Wq8BeMor5IQ/SVhFkzHai5I/AAAAAAAAACs/bnOuWjpyhIw/s640/SilicateGlueIngredients.jpg"><img style="margin: 0pt 0pt 10px 10px; float: right; cursor: pointer; width: 267px; height: 200px;" src="http://lh6.ggpht.com/_Wq8BeMor5IQ/SVhFkzHai5I/AAAAAAAAACs/bnOuWjpyhIw/s640/SilicateGlueIngredients.jpg" alt="" border="0" /></a>Here is an example of embedding a Picasa image...

I hope this helps. It shouldn't be necessary to study the HTML. If the Blogspot controls are cooperative, it should be generated automatically. If they don't cooperate, the HTML could be cut and pasted.

Tuesday, December 23, 2008

Encouraging news about mechanosynthesis

The two items of real interest in the CRN blog posting are these.

First, Philip Moriarty, a scientist in the UK, has secured a healthy chunk of funding to do experimental work to validate the theoretical work done by Ralph Merkle and Rob Freitas in designing tooltips and processes for carbon-hydrogen mechanosynthesis, with the goal of being able to fabricate bits of diamondoid that have been specified at an atomic level. If all goes well, writes Toth-Fejel:

Four years from now, the Zyvex-led DARPA Tip-Based Nanofabrication project expects to be able to put down about ten million atoms per hour in atomically perfect nanostructures, though only in silicon (additional elements will undoubtedly follow; probably taking six months each).Second is that people are now starting to use small machines to build other small machines, and to do so at interesting throughputs. An article at Small Times reports:

Dip-pen nanolithography (DPN) uses atomic force microscope (AFM) tips as pens and dips them into inks containing anything from DNA to semiconductors. The new array from Chad Mirkin’s group at Northwestern University in Evanston, Ill., has 55,000 pens - far more than the previous largest array, which had 250 pens.So there are two take-home messages here. First, researchers are getting ready to work with the large numbers of atoms needed to build anything of reasonable size in a reasonable amount of time. Second, this stuff is actually happening rather than remaining a point of academic discussion.

Toth-Fejel writes:

What happens when we use probe-based nanofabrication to build more probes? ...What happens when productive nanosystems get built, and are used to build better productive nanosystems? The exponential increase in atomically precise manufacturing capability will make Moore’s law look like it’s standing still.Interesting stuff.

Monday, December 08, 2008

Cui's work on cancer with granulocytes

Granulocytes are a particular sort of white blood cell. Read the original New Scientist article or a related article in Science Daily. See a video of granulocytes attacking cancer cells. The video above is a talk by the primary investigator, Zheng Cui. I learned about this in stumbling across the fact that Chris Heward is seeking granulocyte donors.

Zheng Cui at Wake Forest University of Medicine in Winston-Salem, North Carolina, took blood samples from more than 100 people and mixed their granulocytes with cervical cancer cells. While granulocytes from one individual killed around 97 per cent of cancer cells within 24 hours, those from another healthy individual only killed around 2 per cent of cancer cells. Average cancer-killing ability appeared to be lower in adults over the age of 50 and even lower in people with cancer. It also fell when people were stressed, and at certain times of the year. "Nobody seems to have any cancer-killing ability during the winter months from November to April," says Cui.

Elsewhere, Cui wrote: "In 1999, we encountered a unique mouse that refused to succumb to repeated challenges with lethal cancer cells that uniformly killed all other laboratory mice, even at much lower doses. Further studies of this phenotype reveal that this unusual cancer resistance is inheritable and entirely mediated by the macrophages and neutrophils of the innate immunity. Transfer of leukocytes with this high level of cancer-killing activity (CKA) from these cancer-resistant mice cures the most aggressive advanced cancers in other mice without any side effect. Most surpisingly, a similar activity of killing cancer cells was discovered in the granulocytes and monocytes of some healthy people." When applied clinically, this is called LIFT, or "leukocyte infusion therapy".

Cui readily admits that he has not yet done much to explore the precise mechanisms involved. For the present, he is more interested in getting the treatment through clinical trials and into clinical practice. So he has gotten very little support from the medical community, and it's been difficult to secure funding for clinical trials.

Friday, December 05, 2008

Adventures in protein engineering

Why don't we already have a busy protein-based manufacturing base? Because the necessary technologies have arisen only in the last couple of decades, and because older technologies already have a solid hold on the various markets that might otherwise be interested in protein-based manufacturing. Finally, most researchers working with proteins aren't thinking about creating a new manufacturing base. But people in the nanotech community are thinking about it.

One of the classical scientific problems involving proteins is the "protein folding problem". Every protein is a sequence of amino acids. There are 20 different amino acids, which are strung together by a ribosome to create the protein. As the amino acids are strung together, the protein starts folding up into a compact structure. The "problem" with folding is that for any possible sequence of amino acids, it's not always possible to predict how it will fold up, or even whether it will always fold up the same way each time.

But maybe you don't need a solution for all possible sequences. Maybe you can limit yourself to just the sequences that are easy to predict. People have been studying proteins for a long time and it's easy to put together a much shorter list of proteins whose foldings are known. Discard any proteins that sometimes fold differently, to arrive at a subset of proteins whose foldings are well known and reliable.

The next issue is extensibility. Having identified a set of proteins whose foldings are easily predictable, would it be possible to use that knowledge to predict the foldings of larger novel amino acid sequences? A trivial analogy would be that if I know how to pronounce "ham" and I know how to pronounce "burger", then I should should know how to pronounce "hamburger". A better analogy would be Lego bricks or an Erector set, where a small alphabet of basic units can be used to construct a vast diversity of larger structures.

If we can build a large diversity of big proteins and predict their foldings correctly, we're on to something. Then we can design things with parts that move in predictable ways. Some proteins (like the keratin in your fingernails or a horse's hooves) have a good deal of rigidity, and we can think about designing with gears, cams, transmissions, and other such stuff.

Thursday, November 20, 2008

Gustav Mahler's Symphony No. 4 in G major

performed by the Vienna Philharmonic Orchestra (Wiener Philharmoniker), conducted by Leonard Bernstein

Friday, November 07, 2008

Cell-level simulation and hobbyist participation

A lot of the important things that happen in medicine are happening at the cellular level. Cell-level simulators might provide a way for large numbers of hobbyist medical researchers to construct and test hypotheses. The most promising hypotheses might be testable in real biology laboratories, and the results could be fed back to improve the accuracy of the simulators.

I'm not sure this would be an effective strategy for hastening the pace of medical progress. My intuition is biased because I've spent the last fifteen years working with open-source software (Linux, Apache, etc). I recognize that competition and profit are also powerful forces driving the rate of innovation, and that these seem to work best when people aren't sharing information so readily. The software/internet world has seen lots of progress in the last ten or twenty years, and it seems that a mixed environment with both open-source and closed-source approaches has pushed things along well.

Software is difficult but biology is much more difficult. At least it looks that way from my software engineer's point of view. The depth of expertise required for meaningful contribution to medical knowledge will likely exclude most would-be contributors. I don't know what to do about that. Perhaps cell simulators and on-line information can make that expertise more accessible.

Participation by hobbyists has become a very big part of the astronomy community. Maybe there is a legitimate place for hobbyists in the field of medical research.

Thursday, November 06, 2008

First post

Here is today's nifty piece of medical progress, an advance in the fight against cancer. A couple years ago, an unfortunate woman died of acute myelogenous leukemia, leaving behind samples of her cells, some healthy and some cancerous. A team at Washington University in St. Louis was able to sequence the DNA from the cells and compare her healthy DNA to her cancerous DNA. This became possible because the price of DNA sequencing equipment has come down by a very large factor in recent years.

Here is today's nifty piece of medical progress, an advance in the fight against cancer. A couple years ago, an unfortunate woman died of acute myelogenous leukemia, leaving behind samples of her cells, some healthy and some cancerous. A team at Washington University in St. Louis was able to sequence the DNA from the cells and compare her healthy DNA to her cancerous DNA. This became possible because the price of DNA sequencing equipment has come down by a very large factor in recent years.They identified ten point mutations that differentiated the sick cells from the healthy ones. Two of the mutations were already known from earlier research, the other eight mutations were previously unknown. The team is continuing to study differences in the non-coding DNA as well, and they are also preparing to apply the same sequencing methodology to other cancers.

Because they were using DNA samples all from the same person, there would be very few differences among the healthy cells, just the infrequent cell-to-cell mutations that might occur in an average healthy person's body. So they had a good solid statistical baseline that made the ten cancer-related mutations really clear.

It may be years before this translates into clinical practice that saves lives. But it's nevertheless an important advance. It's something that has never been done before, and it does bring to light a few new facts. It looks strongly like point mutations are the cause of at least some, possibly all, cancers. We strongly suspected that before but this almost proves it. One of the ten mutations was present in only a fraction of the cancerous cells, suggesting that the mutations typically occur in a particular sequence, with the last one finally making the cell dangerous.

I'm interested in what social and economic factors could most hasten the rate of medical progress. My reason for this interest is simple: I'm not young any more. I'm curious about whether the development model that has been so successful for open-source software could somehow be applied to quicken the pace of medical progress.

Wednesday, September 03, 2008

Beethoven on Youtube

I also like some of the symphonies. Here's Herbert von Karajan conducting the Seventh Symphony, which I think doesn't get enough attention by comparison to the Third (1, 2, 3? 4?) or the Fifth or the Ninth (1, 2, 3a, 3b, 4). Why is it the only even-numbered Beethoven symphony you ever hear is the Sixth? In fact, none of Beethoven's power-of-two symphonies (numbers 1, 2, 4 and 8) get much airplay. Wierd.

Monday, August 25, 2008

Bach on YouTube

Brandenburg Concerto number 3, probably my favorite: first movement, second movement, third movement. For the third Brandenburg, Bach didn't really write a second movement. He just wrote a couple of chords and allowed the musicians to improvise whatever they wanted within that minimal harmonic constraint. Different groups do different things with that freedom. The first time I heard this concerto was Walter Carlos's rendition on the Switched-on Bach album back in the seventies, which included a lot of interesting sounds that people now associate with old bad sci-fi movies. But at the time, Carlos was one of the first explorers of electronic music and there wasn't yet an esthetic for it. In a later recording Carlos did something a bit more conventional, a minimal expansion on Bach's two chords with just a few flourishes.

Brandenburg Concerto number 3, probably my favorite: first movement, second movement, third movement. For the third Brandenburg, Bach didn't really write a second movement. He just wrote a couple of chords and allowed the musicians to improvise whatever they wanted within that minimal harmonic constraint. Different groups do different things with that freedom. The first time I heard this concerto was Walter Carlos's rendition on the Switched-on Bach album back in the seventies, which included a lot of interesting sounds that people now associate with old bad sci-fi movies. But at the time, Carlos was one of the first explorers of electronic music and there wasn't yet an esthetic for it. In a later recording Carlos did something a bit more conventional, a minimal expansion on Bach's two chords with just a few flourishes.One thing I never quite got about the first Brandenburg (first, second, third, fourth movements) is some funny work in the horns in the first movement. There are points where they just seem off-tempo with everybody else. When I first heard this I assumed the musicians had gotten lost. But now I'm hearing it in this second recording, so I have to conclude that Bach wrote it that way. Maybe he was trying to make sure the listener was awake? Perplexing.

I once read a review of the sixth Brandenburg (first, second, third movements) suggesting that it was a musical description of goings-on in the Bach household. Bach had lots of kids, all presumably running and bouncing about as kids will do, and this is a very busy concerto with a lot happening. So that might be what Bach had in mind, and it especially sounds that way in the third movement which has a real bounce to it. In this recording the cellos (maybe basses? I'm never sure) at the right end seem to have many more than four strings.

Tuesday, August 12, 2008

Multimachine

Multimachine, built by Pat Delany of Palestine, Texas, is an inspiring project. It is...

Multimachine, built by Pat Delany of Palestine, Texas, is an inspiring project. It is...a humanitarian, open source machine tool project for developing countries... The MultiMachine all-purpose machine tool can be built by a semi-skilled mechanic with just common hand tools. For machine construction, electricity can be replaced with "elbow grease" and the necessary material can come from discarded vehicle parts. What can the MultiMachine be used for in developing countries?The project is open source and thoroughly documented. It uses commonly available pieces. It seeks explicitly to address the needs of the developing world. It recognizes the work people did in this area (1, 2) in years past. Cool stuff. We have all kinds of Industrial Revolution era mill buildings in the greater Boston area and this would fit right in.

AGRICULTURE...

WATER SUPPLIES...

FOOD SUPPLIES: Building steel-rolling-and-bending machines for making fuel efficient cook stoves and other cooking equipment...

TRANSPORTATION...

EDUCATION...

JOB CREATION...

Monday, July 21, 2008

3d printer project at Victoria University of Wellington School of Design

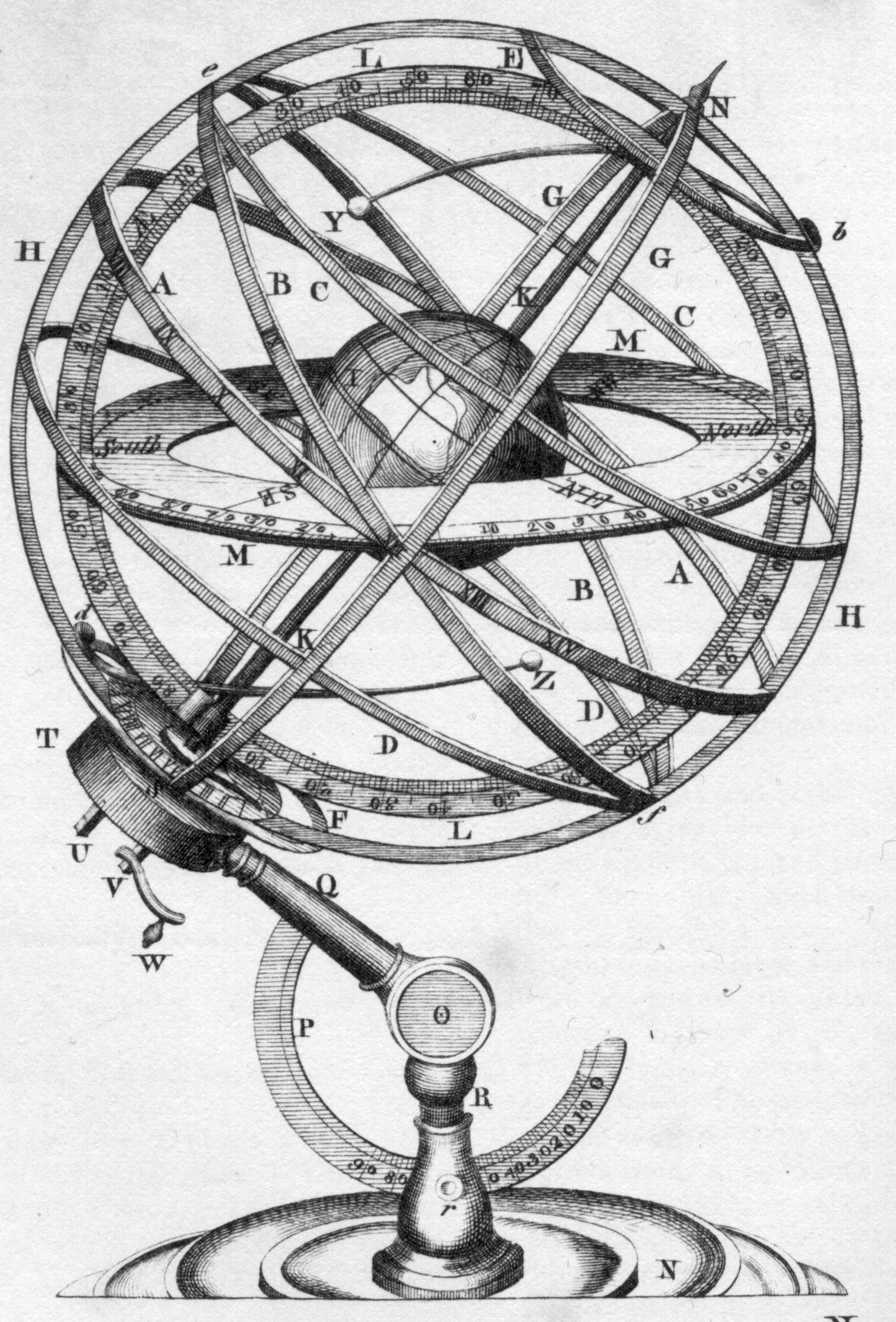

There was recently a design contest at VUW School of Design to create inexpensive 3d printers. Apparently Ponoko had some involvment, possibly a sponsorship. I found the prettiest printer to be the Equinox, which also was designed to be environmentally friendly, using a lens to focus sunlight to dry recycled paint as a printing process. I was going to say the printer itself looks like an astrolabe, but it really looks like an armillary sphere, a sort of 3D astrolabe.

There was recently a design contest at VUW School of Design to create inexpensive 3d printers. Apparently Ponoko had some involvment, possibly a sponsorship. I found the prettiest printer to be the Equinox, which also was designed to be environmentally friendly, using a lens to focus sunlight to dry recycled paint as a printing process. I was going to say the printer itself looks like an astrolabe, but it really looks like an armillary sphere, a sort of 3D astrolabe.Very slow progress on my CNC mill. I finally purchased the 3-axis Xylotex controller. It is my hope to connect it this evening and conceivably mill a piece of wood. So I need to move a PC to where the mill is, run a network cable, load the PC with EMC and configure it, and set up the shop-vac to collect sawdust. I'll mount the Xylotex board and power supply and fan on the side of the mill, but that's for later.

Wednesday, July 02, 2008

Penny wise, pound foolish

- Xylotex three-axis controller with power supply

$205 plus shipping - Xylotex four-axis controller with power supply

$235 plus shipping - Xylotex FAQ

The mechanics cost about $300 including shipping. The steppers cost $75 (I got them from RRRF). This stepper controller will run maybe $225 with shipping, so the whole thing is $600. That's reasonable. Obviously it doesn't include waste.

I'm thinking it would be fun to fool with Python code that generates G code and sends it to the CNC. I could develop a repertoire of programmatically defined shapes.

Friday, June 06, 2008

RepRap replicates, and Will gets a New Toy

On the left is Adrian Bowyer, the University of Bath professor who started the RepRap project. On the right is Vik Olliver, the most active RepRap builder on the planet. The two machines marked "parent" and "child" are RepRap 3D printers with the interesting relationship that the "child" was mostly built by the "parent". This is a HUGE STEP toward Bowyer's vision wherein RepRaps make more RepRaps and humans benefit. This will do for physical goods what the GPL and Linux and Apache have done for software.

On the left is Adrian Bowyer, the University of Bath professor who started the RepRap project. On the right is Vik Olliver, the most active RepRap builder on the planet. The two machines marked "parent" and "child" are RepRap 3D printers with the interesting relationship that the "child" was mostly built by the "parent". This is a HUGE STEP toward Bowyer's vision wherein RepRaps make more RepRaps and humans benefit. This will do for physical goods what the GPL and Linux and Apache have done for software. My own news is, at least locally, equally exciting. My CNC mill has finally arrived! And I also got an Arduino controller. I've got my stepper motors from RRRF, and a Harbor Freight router is on the way. It's going to take time to put everything together, and of course there's very little spare time in the life of a modern adult.

My own news is, at least locally, equally exciting. My CNC mill has finally arrived! And I also got an Arduino controller. I've got my stepper motors from RRRF, and a Harbor Freight router is on the way. It's going to take time to put everything together, and of course there's very little spare time in the life of a modern adult. Once the CNC mill is up and running, I plan to work on a scheme for swapping out the router and swapping in an extruder for thermoplastic. By that time the RepRap guys will be doing even better than they're doing today, so I will benefit from their stuff. Maybe I'll end up making an actual RepRap before I'm through.

Once the CNC mill is up and running, I plan to work on a scheme for swapping out the router and swapping in an extruder for thermoplastic. By that time the RepRap guys will be doing even better than they're doing today, so I will benefit from their stuff. Maybe I'll end up making an actual RepRap before I'm through.

Thursday, May 29, 2008

RepRap: Big step up in print quality!

This posting on the RepRap blog shows the massive progress these guys have made recently in their printing quality. The progression is clearly visible in this photo of some door handles. The most recent incarnation is the work of a guy known as "Nophead", with his own blog describing his work. His machine uses a RepRap extruder on a purchased CNC table rather than the RepRap 3D platform, which made me think that the RepRap platform must be the reason for the less-than-commercial-grade print quality. I asked him about this in a comment, and he replied that the improvements were:

This posting on the RepRap blog shows the massive progress these guys have made recently in their printing quality. The progression is clearly visible in this photo of some door handles. The most recent incarnation is the work of a guy known as "Nophead", with his own blog describing his work. His machine uses a RepRap extruder on a purchased CNC table rather than the RepRap 3D platform, which made me think that the RepRap platform must be the reason for the less-than-commercial-grade print quality. I asked him about this in a comment, and he replied that the improvements were:- his extruder has a shaft encoder to control the speed precisely

- he has temperature control to +/- 3C

- he doesn't have any comms delays (I don't know the architecture well enough to know exactly what he means here)

- he runs his head faster so as to stretch the filament down to 0.5mm.

- careful choice of printing material

Within just a year or two, RepRap will be much further along in terms of both quality and ease of use, and it will be affordable for small clubs in high schools and colleges all over the world, and large numbers of individual hobbyists. By then it will probably print multiple materials including conductive ones, so you'll be able to embed circuitry in a widget. Today one of the big killer apps for 3D printers is little action figures based on avatars from Second Life and similar games, but when 3D printers really are ubiquitous, people will move on to far more interesting apps that I can hardly imagine.

Let me not forget this very nice list of a lot of different commercial and hobbyist 3D printers.

Still waiting for my CNC mill platform, the eBay fellow has been getting a huge volume of business and his shop is a bit swamped. I've been getting a bit more organized with the electronics, including resuscitating an old FX2 board design, and I've ordered some stepper motor driver parts that should arrive soon.

Wednesday, May 07, 2008

Affordable CNC gadgets

CNC has existed as a hobbyist pursuit much longer than 3D printers have been. I finally broke down and purchased one of these on eBay. It will take a couple weeks to arrive, and the one I got did not include stepper motors, couplers, or motor drive electronics. Those are things I'd enjoy doing myself anyway, so no problem.

CNC has existed as a hobbyist pursuit much longer than 3D printers have been. I finally broke down and purchased one of these on eBay. It will take a couple weeks to arrive, and the one I got did not include stepper motors, couplers, or motor drive electronics. Those are things I'd enjoy doing myself anyway, so no problem. I like this project which is along similar lines.

I like this project which is along similar lines.For my own gadget, I need to order stepper motors, think about couplers, and start planning how the electronics will go together. I'm thinking about being lazy and using the parallel port.

I got to see a real RepRap up close!

This evening I went to a presentation and demonstration of a real live RepRap by Bruce Wattendorf and his son. It was very cool to meet somebody who's built a real one and is totally up to speed on every aspect of the project. I asked some questions about the long-term future of the RepRap project.

This evening I went to a presentation and demonstration of a real live RepRap by Bruce Wattendorf and his son. It was very cool to meet somebody who's built a real one and is totally up to speed on every aspect of the project. I asked some questions about the long-term future of the RepRap project.- Can they get much better spatial resolution without compromising the social goal of serving the developing world? Yes: better spatial resolutions can be gotten with finer nozzles, which would print slower. You could build a duel-nozzle gadget with a wide nozzle for fast clumsy printing, and a narrow fine nozzle for slow elegant finishing.

- Will they bump into patent problems as they move toward the state of the art currently occupied by commercial 3D printers? A number of patents will expire in about three years and the RepRap guys will then be much freer in this area.

He wrapped up his presentation by showing the nanofactory video, "Productive Nanosystems: from Molecules to Superproducts". I came to 3D printers from an interest in nanotech, and he came to nanotech from working on 3D printers. It was gratifying to see that the similarity is clear to people on the other side of the fence.

He wrapped up his presentation by showing the nanofactory video, "Productive Nanosystems: from Molecules to Superproducts". I came to 3D printers from an interest in nanotech, and he came to nanotech from working on 3D printers. It was gratifying to see that the similarity is clear to people on the other side of the fence.It was a heck of a lot of fun. I took some pictures. Bruce also has many more pictures on his blog. Interestingly, the parts that are normally plastic in a RepRap are made of wood in Bruce's machine, and he's in the process of printing a set of plastic parts.

Bruce's talk was sponsored by a group called DC401, a bunch of Rhode Island folks who enjoy going to DefCon. They are working with a woman in real estate to arrange a lab space in a building in downtown Providence where they can do electronic and mechanical tinkering. It was fascinating to hear her talk about how she's making it all work by using the other floors for businesses and residential space. This reminds me a lot of MITERS, and it warms my heart.

Tuesday, May 06, 2008

More developments in cancer treatment

Here are some more new cancer therapies under development. Many of these involve some flavor of nanoparticle (a fancy word for a molecule), and a few involve nanomachines (a molecule that does something more interesting than just sitting there).

Here are some more new cancer therapies under development. Many of these involve some flavor of nanoparticle (a fancy word for a molecule), and a few involve nanomachines (a molecule that does something more interesting than just sitting there).- http://www.technologyreview.com/Nanotech/18999/ -- The new nanoengineered system, designed by physician and researcher James Baker and his colleagues at the University of Michigan, contains gold nanoparticles with branching polymers called dendrimers that sprout off the nanoparticle's surface. The particles could be used to launch a multiprong attack against tumors. The dendrimer arms can carry a number of different molecules, including molecules that target cancer cells, fluorescent imaging agents, and drugs that slow down or kill the cells. Once enough of the nanoparticles have gathered inside cancer cells, researchers could kill the tumors by using lasers or infrared light to heat up the gold nestled inside the dendrimers.

- http://www.technologyreview.com/NanoTech/wtr_16690,319,p1.html -- A single treatment of drug-bearing nanoparticles effectively destroys prostate cancer tumors in mice ...the researchers mix together a prostate cancer drug (docetaxel) and polymers that are already FDA-approved... The polymer formed spheres with the drugs trapped within. The researchers then chemically attach pieces of RNA, called aptamers, to the surface of the spheres. The RNA folds into shapes that fit into complementary structures on the surface of prostate-cancer cells... [In placebo groups] almost all the mice died during the experiment. In contrast, all of the mice injected with the targeted nanoparticles survived, and in most cases (five out of seven) the tumors disappeared.

- http://www.rsc.org/publishing/journals/CC/article.asp?doi=b800528a -- We present experimental data that demonstrate the potential of synthetic crown ether modified peptide nanostructures to act as selective and efficient chemotherapeutic agents that operate by attacking and destroying cell membranes.

- http://www.eurekalert.org/pub_releases/2008-03/uoc--urd033108.php -- Researchers from the Nano Machine Center at the California NanoSystems Institute at UCLA have developed a novel type of nanomachine that can capture and store anticancer drugs inside tiny pores and release them into cancer cells in response to light... the device is the first light-powered nanomachine that operates inside a living cell... [reported on] March 31 in the online edition of the nanoscience journal Small.

- http://mednews.wustl.edu/news/page/normal/11449.html -- The nanoparticles are extremely tiny beads of an inert, oily compound that can be coated with a wide variety of active substances. In an article published online in The FASEB Journal, the researchers describe a significant reduction of tumor growth in rabbits that were treated with nanoparticles coated with a fungal toxin called fumagillin. Human clinical trials have shown that fumagillin can be an effective cancer treatment in combination with other anticancer drugs... the nanoparticles' surfaces held molecules designed to stick to proteins found primarily on the cells of growing blood vessels. So the nanoparticles latched on to sites of blood vessel proliferation and released their fumagillin load into blood vessel cells. Fumagillin blocks multiplication of blood vessel cells, so it inhibited tumors from expanding their blood supply and slowed their growth.

- http://nano.cancer.gov/news_center/2008/feb/nanotech_news_2008-02-15c.asp -- ...Regulators and drug developers are concerned that these delivery systems may prove difficult to manufacture on a consistent basis... A new study from James Baker, Jr., M.D., PI, Cancer Nanotechnology Platform Partnership at the University of Michigan, and colleagues provides data showing that such concerns can be overcome... the investigators present the results of studies designed to show that they could achieve consistent and specific targeting and cell-killing activity across multiple manufacturing batches of a dendrimer-based therapeutic agent.

- http://www.physorg.com/news82653370.html -- A team of investigators has designed a nanoscale, polymeric drug delivery vehicle that when loaded with a widely used anticancer agent cures colon cancer in mice with a single dose... To create their drug delivery vehicle, the investigators used a highly branched polymer, known as a dendrimer, that naturally forms nanoparticles with myriad sites for drug loading. In this particular case, the researchers created what they call a bow-tie polyester dendrimer, whose molecular structure somewhat resembles a bow-tie with two discrete halves... On one half of the dendrimer, the researchers attached a second polymer, poly(ethylene glycol) (PEG), in order to make the dendrimer water soluble... Next, the investigators attached the anticancer drug doxorubicin to the other half of the dendrimer using a chemical linkage designed to break when exposed to acidic conditions. Not coincidentally, the inside of tumor cells is acidic, while the bloodstream has a neutral pH. Results presented in this paper show that the resulting drug-dendrimer formulation releases virtually all of its drug within 48 hours in acidic conditions but less than 10 percent of its payload at neutral pH.

- http://www.azonano.com/news.asp?newsID=4087 -- A new type of cancer detector... the simple and inexpensive system, which can be built from off-the-shelf components, can rapidly detect the presence of cancer biomarkers – telltale proteins in body fluids that can signal the presence of malignant tumors – at very low levels... “With this technology, a future scenario might be that you go to the doctor every year for an annual checkup; he draws about 10 cc’s of your blood and runs it through our machine,” said Soman. “The machine is equipped to detect the biomarkers for all the common types of cancer. Half an hour later it produces a list of the biomarkers that it has found. And then either a software program or the physician examines this list to determine whether you have any cancers that need treating.”

- http://nanotechwire.com/news.asp?nid=4703 -- There is a growing recognition among cancer researchers that the most accurate methods for detecting early-stage cancer will require the development of sensitive assays that can identify simultaneously multiple biomarkers associated with malignant cells. Now, using sets of nanoparticles designed to aggregate in response to finding more cancer biomarkers, a team of researchers funded by the Alliance for Nanotechnology in Cancer has developed a multiplexed analytical system that could detect cancer using standard magnetic resonance imaging (MRI).

- http://www.forbes.com/claytonchristensen/2008/02/22/cancer-nanotechnology-therapies-lead-clayton-in_jw_0222claytonchristensen_inl.html -- A survey of several different developments, but not much deep discussion of any of them. More of a businessman's-eye view of things, not too surprising for Forbes.

Sunday, April 27, 2008

TAT variant with magnetic particles

My last posting about targeted alpha therapy discussed the expense of preparing a sample of radioactive actinium, aside from which, targeted alpha therapy should be a very effective and specific and hopefully affordable cancer therapy. Quentin Pankhurst of the London Centre for Nanotechnology has been working with particles of iron oxide, which has very low toxicity and can be attached to antibodies just like the actinium atoms in cages. Iron oxide can be magnetized so each particle can be a permanent magnet. A magnetized particle can then be detected from outside the body using a weak EM field generated by a hand-held device, or it can be heated with a strong EM field, to the point of destroying the cancer cell .

My last posting about targeted alpha therapy discussed the expense of preparing a sample of radioactive actinium, aside from which, targeted alpha therapy should be a very effective and specific and hopefully affordable cancer therapy. Quentin Pankhurst of the London Centre for Nanotechnology has been working with particles of iron oxide, which has very low toxicity and can be attached to antibodies just like the actinium atoms in cages. Iron oxide can be magnetized so each particle can be a permanent magnet. A magnetized particle can then be detected from outside the body using a weak EM field generated by a hand-held device, or it can be heated with a strong EM field, to the point of destroying the cancer cell .By combining the iron oxide particle with an antibody for the HER2 protein found in breast cancer cells, Pankhurst should be able to achieve the same specificity and effectiveness that Sloan-Kettering has gotten with radioactive actinium, at vastly lesser cost. In order to commercialize this and related applications, Pankhurst has founded Endomagnetics, a start-up based in Houston, Texas.

Why should iron oxide be so much less expensive than radioactive actinium? "Iron oxide" is the chemical name for rusty metal, which is easy to make and store, and readily available in auto scrap yards everywhere. Actinium-225, the isotope used for TAT, has a half-life of ten days, so you can't make a big batch and store some for later use. According to this website at the Oak Ridge National Laboratory: "The actinium-225 is formed from radioactive decay of radium-225, the decay product of thorium-229, which is obtained from decay of uranium-233. The National depository of uranium-233 is at ORNL, and we have developed effective methods for obtaining thorium-229 (half-life 7340 years) as our feed material to routinely obtain actinium-225."

Wednesday, April 23, 2008

RepRap replicates 100%

This story in Computerworld is a couple weeks old, and I should be working harder to keep up. Vik Olliver, a RepRap hacker in New Zealand (and probably the hardest-working RepRap hacker in the world), has now fabricated all the parts of the RepRap except the Z flag, which can be cut out of the side of a beer can. This includes only the parts that it makes sense to print on a RepRap, so it doesn't include stepper motors, nuts and bolts, pieces of metal and wood (e.g. threaded rods). But it's an important step.

This story in Computerworld is a couple weeks old, and I should be working harder to keep up. Vik Olliver, a RepRap hacker in New Zealand (and probably the hardest-working RepRap hacker in the world), has now fabricated all the parts of the RepRap except the Z flag, which can be cut out of the side of a beer can. This includes only the parts that it makes sense to print on a RepRap, so it doesn't include stepper motors, nuts and bolts, pieces of metal and wood (e.g. threaded rods). But it's an important step. I myself am still drooling a bit over some of the hobbyist CNC stuff. There's a guy in New Mexico who sells these things on eBay. He sells aluminum ones (like this) and ones made of MDF, which I believe is a sort of particle board. Many low-end CNC machines are in the $2000 to $5000 ballpark, whereas he sells these in the $300 to $600 ballpark. It should be pretty easy to swap out that orange router and swap in an extruder.

I myself am still drooling a bit over some of the hobbyist CNC stuff. There's a guy in New Mexico who sells these things on eBay. He sells aluminum ones (like this) and ones made of MDF, which I believe is a sort of particle board. Many low-end CNC machines are in the $2000 to $5000 ballpark, whereas he sells these in the $300 to $600 ballpark. It should be pretty easy to swap out that orange router and swap in an extruder.I was thinking a bit last night about how to drive those steppers, since the offerings on eBay don't include the drive electronics. Digikey sells a stepper motor sequencer chip, the L297, which would be used to drive some power MOSFETs. The L297 just needs an input to choose clockwise or counter-clockwise, and a clock pulse to advance a step in that direction, so you need six GPIO lines to control the three motors, and one more to turn on/off the router or squirt goop out of the extruder. There's some very good information on stepper motors and driver circuits here.

It occurs to me that I've never posted the Sourceforge download page for the RepRap design files. A shocking oversight, given that I want to see the project succeed and proliferate.

Monday, April 21, 2008

Targeted alpha therapy

At Sloan-Kettering where this work was done, they applied for a patent. A clinical trial was conducted in 2002 with favorable results. There have also been some clinical trials in Australia, I believe.

As far as I am aware, this is a fantastic treatment, due to its being extremely specific, and is applicable to a wide range of cancers, but it's not used much. I would imagine the actinium-255 must be prepared through some process that would probably be very expensive. It would be great if some more affordable alternative could be found. It seems to me that were advanced nanotech available today, some suitable replacement for the radioactive actinium nucleus might be possible.

Nifty stuff over at Machine Phase blog

A couple of interesting things from Tom Moore's Machine Phase blog. One is a comparison between a carbon buckyball and a geometrically similar structure made from DNA using (what appears to be) Paul Rothemund's DNA origami technique. Note the teeny dot in the middle, that's the carbon buckytube.

A couple of interesting things from Tom Moore's Machine Phase blog. One is a comparison between a carbon buckyball and a geometrically similar structure made from DNA using (what appears to be) Paul Rothemund's DNA origami technique. Note the teeny dot in the middle, that's the carbon buckytube.The other is very interesting because it combines nanotech with my interest in 3d printers in an unexpected way. Specifically it's about using a 3d printer to print parts for an atomic-force microscope, using selective laser sintering. These microscopes typically cost hundreds of thousands of dollars. Hopefully this approach will make them much more affordable for universities, and perhaps high schools and even individual hobbyists.

The white plastic pieces were the things printed with the 3d printer. I always thought of SLS as something done with metal, but I guess it works with plastic too.

Wednesday, March 26, 2008

My trip to Munich, 20-25 March 2008

For the moment this blog entry is only a placeholder, later I'll fill in more details. The itinerary was roughly as follows. Wednesday night, took a red-eye from Boston to London Heathrow, landing at 6 AM local time and spending six hours learning about unreasonable exchange rates. Then a two hour flight to the Munich airport near Erding where Bob lives and works.

View Larger Map

On Friday we went to the Museum Mensch und Natur (map) in downtown Munich. On Saturday we went to Herrenchiemsee, a palace on an island in the middle of a lake, modeled after Versailles in France. On Sunday we went to the Deutsches Museum (photos, map) in Munich, and I've got to say, it's the best science and technology museum I have ever seen in my life. On Monday we went to the castle complex at Burghausen, on the Austrian border. On Tuesday I was too frantic catching my plane for any interesting adventures, although Bob and I did bike into town to get strawberries and fresh croissants.

Thursday, March 13, 2008

Nanotube radio antenna work at U.C. Berkeley

Alex Zettl at the University of California at Berkeley has invented an interesting radio antenna made from a single conductive carbon nanotube (less than a micron long and ten nanometers wide) positioned between two conductive plates. He has used the antenna to receive songs transmitted by radio, and has posted the results for your listening pleasure. There is a gap between one plate and a free end of the nanotube, across which electrons tunnel. When a voltage is placed across the two plates, the nanotube's free end becomes electrically charged oppositely from the nearby plate, and the electrostatic attraction keeps the nanotube under mechanical tension.

Alex Zettl at the University of California at Berkeley has invented an interesting radio antenna made from a single conductive carbon nanotube (less than a micron long and ten nanometers wide) positioned between two conductive plates. He has used the antenna to receive songs transmitted by radio, and has posted the results for your listening pleasure. There is a gap between one plate and a free end of the nanotube, across which electrons tunnel. When a voltage is placed across the two plates, the nanotube's free end becomes electrically charged oppositely from the nearby plate, and the electrostatic attraction keeps the nanotube under mechanical tension.The nanotube's electrically charged free end moves in response to an ambient radio frequency electric field. This changes the gap size, and therefore the measured tunneling current across the gap, just as with a scanning tunneling microscope. The resonant frequency of the antenna is simply the mechanical resonant frequency of the nanotube under tension. The tension can be changed by changing the voltage across the two conducting plates, and in this way the radio can be tuned. The bandwidth of the antenna is determined by the nanotube's stiffness, and (I think) would depend primarily on the length of the nanotube. The space between the two plates should be a vacuum so the nanotube can move freely, and so that Brownian motion does not detune the radio.

The value of a radio antenna this size is that one can communicate with and control nanorobots, for instance in the human body. One could use these nanorobots for diagnostics, reading out blood chemistry or information about various kinds of cell damage, and could send them instructions to intervene.

There are lots of interesting things happening in the area of nanofabrication, such as Andrew Turberfield's tetrahedra discussed in the previous posting. Presently such things are "controlled" by adding solutions of different DNA sequences to the liquid the structure is sitting in, and the new sequence interacts mechanically with the structure to alter it, by binding selectively with some part of the structure already in place. But each step takes tens of minutes as molecules diffuse through water and position themselves to bind correctly. A signal received by a radio antenna might make things happen much quicker.

Thursday, March 06, 2008

Adrian Bowyer interview, Computerworld

The Fab@Home people have already done a few embedded circuits by printing with conductive silicone. Making circuitry will be a very important ability for these machines.Are there plans to modify the current design to replace non-reproducible parts such as bolts with parts that can be manufactured on the machine itself, bringing the overall RepRap design closer to 100 per cent self-reproduction?

Yes - that is definitely one of the evolutionary paths to greater reproductive success. For the immediate future I will be concentrating on widening the list of materials that RepRap can build with (starting with electrical conductors). That widening will implicitly raise the proportion of parts that it can make for itself, of course.

This is the first time I've ever heard anybody advocate for putting stuff INTO landfills as an environmental measure. An interesting approach to carbon sequestration.Can the RepRap recycle what it manufactures?

Yes, recycling has been built in from the start... The main plastic we are using is polylactic acid...

But I want to move to using a non-biodegradable resin. This too is sourced from biomass, but is stable in the ground. That means that the more reprapped goods that get made from it and thrown in landfill, the more carbon is taken out of the atmosphere and locked away for good. And, in 200 years when we have taken so much carbon out of the air to make stuff that anthropogenic global cooling is starting to be a problem, the landfill sites become our strip coal mines to save us.

Sunday, March 02, 2008

Coming soon: a complete RepRap kit

BitsFromBytes.com is an on-line store based in the UK which will be offering a complete set of parts for the RepRap for UK£299, or somewhere around US$600 given current exchange rates. They will offer both hardware and software.

BitsFromBytes.com is an on-line store based in the UK which will be offering a complete set of parts for the RepRap for UK£299, or somewhere around US$600 given current exchange rates. They will offer both hardware and software.I wish I could claim to be so ambitious that I would take a more active approach than simply ordering all the parts in a kit. But I'm as lazy and tired as the next guy, so a kit is really the only practical way I'm likely to do this. And the price is just about right. Months ago, Adrian Bowyer was talking about $400 as a target price for the long term, after lots of self-replicating machines had brought the price of parts down to a minimum. To get so close to the long-term price so quickly is fantastic.

With this kind of head start, the scenario where RepRaps bootstrap themselves to microeconomic ubiquity looks very plausible.

Thursday, February 28, 2008

More service bureaus

Big Blue Saw is a service bureau that does waterjet cutting of metal and plastic. They cut very thick pieces of metal, which surprises me, I didn't know you could do that.

A couple more: Fabjectory.com specializes primarily in making physical copies of avatars from games like SecondLife. FluidForms makes pretty flowing shapes for things like vases and pitchers. I haven't read about these yet, and as of this writing I don't know what technology they use, or what design software.

Broadening the definition of "fabber"

I want to broaden the scope of this blog a bit. The word "fabber" is generally accepted as synonymous with "3D printer" but a 3D printer has a lot in common with both CNC machines (routers for wood or milling machines for metal) and laser cutters. There are hobbyists building all of these. All of them make a 2D or 3D shape under computer control with relatively little human intervention, and minimal need for human skill.

I want to broaden the scope of this blog a bit. The word "fabber" is generally accepted as synonymous with "3D printer" but a 3D printer has a lot in common with both CNC machines (routers for wood or milling machines for metal) and laser cutters. There are hobbyists building all of these. All of them make a 2D or 3D shape under computer control with relatively little human intervention, and minimal need for human skill.How many of these gadgets could be self-replicative in the RepRap sense? For example, could one use a laser cutter

(or a laser-cutting service like Ponoko) to cut out pieces and use those pieces to build another laser cutter, thereby driving down the cost of laser cutters? As with RepRap there will inevitably be complicated pieces that can't be made that way. CO2 lasers are dangerous and expensive, so I don't think this could make the kind of impact in the developing world that RepRap hopes to make. A replicating CNC machine might be a better bet, as Dremel tools are much cheaper and safer than lasers.

(or a laser-cutting service like Ponoko) to cut out pieces and use those pieces to build another laser cutter, thereby driving down the cost of laser cutters? As with RepRap there will inevitably be complicated pieces that can't be made that way. CO2 lasers are dangerous and expensive, so I don't think this could make the kind of impact in the developing world that RepRap hopes to make. A replicating CNC machine might be a better bet, as Dremel tools are much cheaper and safer than lasers.That self-replicative idea does fascinate me a good deal. It will, over time, drive down the price of the self-replicating thing. That doesn't mean we'll enter a microeconomic paradise, but it promises at least to be interesting and possibly to raise the quality of life noticeably.

I've haven't blogged too much about commercial machines. I want to do more of that. I admire the hobbyists and their perseverance in the face of difficulties, but the technology appearing in commercial machines will gradually trickle down into the hobbyist arena as patents expire.

Wednesday, February 27, 2008

RepRap parts available via Ponoko

Toby Borland (of SMARTlab in the U.K.) has designed a set of laser-cut plywood RepRap parts and made the EPS files available on the Ponoko website. There is a Flickr photo set showing laser-cut RepRap parts and the process of assembling them; I am not sure that's the same Ponoko files and process, or another laser-cutting effort, but it gives you a sense of what's involved, and the level of complexity.

Toby Borland (of SMARTlab in the U.K.) has designed a set of laser-cut plywood RepRap parts and made the EPS files available on the Ponoko website. There is a Flickr photo set showing laser-cut RepRap parts and the process of assembling them; I am not sure that's the same Ponoko files and process, or another laser-cutting effort, but it gives you a sense of what's involved, and the level of complexity.

Friday, February 22, 2008

Too-brief overview of DNA nanotechnology

A lot of interesting work has been done with DNA nanotechnology, much of it starting with Nadrian Seeman's work on DNA polyhedra in the mid-90s (1, 2).

A lot of interesting work has been done with DNA nanotechnology, much of it starting with Nadrian Seeman's work on DNA polyhedra in the mid-90s (1, 2).Around 2000, Andrew Turberfield (Oxford University's Department of Physics) used DNA to make tweezers, with arms 7 nanometers long.

"Of course it's all very speculative," said Dr Turberfield, "but you can imagine, for instance, little factories on chips doing chemistry or simple assembly. You can think of production lines made up of little motors with different reactants being passed from one place to the next."

Things got really interesting in March 2006 with Paul Rothemund's DNA origami technique. Here is the publication. I was working at Nanorex at that time, and we were all quite excited about it.

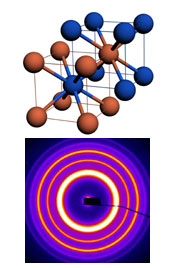

Things got really interesting in March 2006 with Paul Rothemund's DNA origami technique. Here is the publication. I was working at Nanorex at that time, and we were all quite excited about it. In 2005 Turberfield and colleagues described a family of DNA tetrahedra consisting of triangles of DNA helices covalently joined at the vertices to form a mechanically rigid 3D structure. This image of a reduced model of one structure, which is less than 10 nanometers on a side, was created using NanoEngineer-1 Alpha 9. The bowing of the DNA helices is pronounced in this rendering and is the result of electrostatic potential terms included in the customized molecular-mechanics-like force field developed by Dr. K. Eric Drexler specifically for DNA structures. Regarding Turberfield's work, New Scientist wrote:

In 2005 Turberfield and colleagues described a family of DNA tetrahedra consisting of triangles of DNA helices covalently joined at the vertices to form a mechanically rigid 3D structure. This image of a reduced model of one structure, which is less than 10 nanometers on a side, was created using NanoEngineer-1 Alpha 9. The bowing of the DNA helices is pronounced in this rendering and is the result of electrostatic potential terms included in the customized molecular-mechanics-like force field developed by Dr. K. Eric Drexler specifically for DNA structures. Regarding Turberfield's work, New Scientist wrote:Now Andrew Turberfield [et al] have shown how carefully crafted DNA structures can be made to self assemble and change shape when sent specific DNA signals. The researchers built tetrahedrons ... using four short DNA "struts" that join at each end. The process exploits the way DNA is held together by complementary bases that form the rungs of a ladder-like structure ... the researchers made cages with two extendible struts that could be independently controlled using different DNA sequences. In theory, it should be possible to create cages in which every strut can be controlled independently, Tuberfield says.These cages are a combination of support material and linear motor, and with the many other DNA tricks being done, they should allow people to build large, complicated, reasonably rigid 3D structures that have controllable moving parts. So this is a very promising development.

A very recent announcement of work by Chad Mirkin and colleagues. They have found a way to use DNA to glue together arbitrary arrangements of teeny gold spheres. People have known for some time now how to make DNA stick to gold spheres, and by careful selection of DNA sequences, Mirkin et al can position groups of spheres in almost any 3D configuration they want.

A very recent announcement of work by Chad Mirkin and colleagues. They have found a way to use DNA to glue together arbitrary arrangements of teeny gold spheres. People have known for some time now how to make DNA stick to gold spheres, and by careful selection of DNA sequences, Mirkin et al can position groups of spheres in almost any 3D configuration they want.In light of these developments, Nanorex has narrowed its focus from "general" nanotechnology (anything one might build from common small molecules) to structural DNA nanotechnology. This is likely to be where much progress will occur in the next five years or so. I hope Nanorex will still be around after that, and will be in a good position to shift gears as we move beyond DNA to more general chemistry.

Sunday, February 17, 2008

Those commercial 3D printers sure are gittin' purty

In twenty years, all the patents for this printer will have expired, and it will be possible for hobbyists to make such pretty stuff at such high resolution. Hmm, thinking more about that inclines me to start an economics blog, since I blog about economics a lot elsewhere.

Friday, February 15, 2008

An XYZ platform for fabbing or CNC

I was watching an auction for a CNC XYZ table on eBay that went for $300, item number 200198037915. I would have bid on it if the Z travel hadn't been only 2 inches. It was built from plans from hobbycnc.com and didn't have stepper motors or the machining tool but was otherwise complete. I felt lust in my heart, but that itty bitty Z travel bugged me, so I thought about what could be done to increase it. Here's my general idea.

I was watching an auction for a CNC XYZ table on eBay that went for $300, item number 200198037915. I would have bid on it if the Z travel hadn't been only 2 inches. It was built from plans from hobbycnc.com and didn't have stepper motors or the machining tool but was otherwise complete. I felt lust in my heart, but that itty bitty Z travel bugged me, so I thought about what could be done to increase it. Here's my general idea.

My hope is that the blue-hatched stage can be made to take either a Dremel tool for CNC milling, or an extruder for fabbing. The result might or might not be self-replicative in a RepRap sense but it would be a cool toy.

Monday, February 11, 2008

RepRap is now half-way to replication

It's interesting that you can see the size of the volume pixels Vik is working with. These pieces were printed with polylactic acid, I believe.

Unrelated but cool: Kovio is a non-hobbyist company working on a process to inexpensively print working transistors. Early applications will include smart cards, later you'll see wall-sized displays.

Also unrelated but also cool: Fernando Muñiz has been working with UV-cured resins. This will work a bit like the CandyFab, except the uncured resin is still a liquid so under-support structures are still required. Interesting, I'm not sure if it's better or worse than the FDM approach used by RepRap, Fab@Home, and Tommelise. Also, I don't have any idea how environmentally benign these resins are; it's hard to imagine they're as green as polylactic acid.

Saturday, February 09, 2008

Big fabbers: houses, boats, factories

A fabber placing individual drops of building material would be awfully slow for a very large project. One work-around would be to trade away spatial resolution, and let the fabber lay down big handfuls of wet concrete.

Maybe you'd want many fabbers feeding small pieces to an assembler that assembles them into bigger pieces. The assembler must be able to make the small pieces stick together, by gluing them or melting the sides or by using mechanical fasteners such as screws or nuts and bolts. It's possible that the big pieces might then be assembled into very big pieces, and again an assembling machine must be fed from many sources. The assembler would need to be very smart to recognize and correct assembly errors, and would probably need machine vision. This would work well for products from a factory, but might be unsuitable for a house.

A google search for "robot bricklayer" turns up a few modest research efforts. I would have imagined something like the big XYZ stage above with a brick-lifting robot arm, wheeled into position over the site of the future house, but the most advanced effort visible on the web is a standard industrial robot arm picking up bricks instead of doing whatever else robot arms normally do. The arm can't move around the entire volume of the future house, it's not on any sort of XYZ stage, it's just bolted to the floor like any other industrial robot arm. So robotic house construction is still quite a ways off.

A google search for "robot bricklayer" turns up a few modest research efforts. I would have imagined something like the big XYZ stage above with a brick-lifting robot arm, wheeled into position over the site of the future house, but the most advanced effort visible on the web is a standard industrial robot arm picking up bricks instead of doing whatever else robot arms normally do. The arm can't move around the entire volume of the future house, it's not on any sort of XYZ stage, it's just bolted to the floor like any other industrial robot arm. So robotic house construction is still quite a ways off.

Thursday, February 07, 2008

Fabbers as tissue engineering tools

Tommelise project

Tommelise is Forrest Higg's attempt to build his own RepRap-like gadget before RepRap itself is ready for wide distribution. He has spoken at an O'Reilly conference about the RepRap project and he has some fascinating ideas about architecture and how fabbers might relate to it. The recent (early Feb 2008) postings in his Tommelise blog describe his success in connecting stepper motor axles to threaded rods, something I had been wondering about myself.

Tommelise is Forrest Higg's attempt to build his own RepRap-like gadget before RepRap itself is ready for wide distribution. He has spoken at an O'Reilly conference about the RepRap project and he has some fascinating ideas about architecture and how fabbers might relate to it. The recent (early Feb 2008) postings in his Tommelise blog describe his success in connecting stepper motor axles to threaded rods, something I had been wondering about myself.In the Tommelise FAQ, Higgs mentions Linux and Java (which have been adopted by the RepRap project) as presenting a steep learning curve to people without a software background, citing Microsoft Windows and Visual Basic as more user-friendly alternatives. My own early experiences with Linux required enormous patience. Higgs writes Tommelise has been created for people who aren't particularly clever and may be living in modest circumstances. Any open-source "fabber revolution" (1, 2, 3) will be an empty exercise if it fails to serve such people. Then again, if a genuinely open-source revolution is to occur, we'll eventually need to wean ourselves from Microsoft and make our own tools equally user-friendly.

Wednesday, February 06, 2008

Interesting Russian project

They have a great-looking XYZ stage built from a CNC kit. They lower a heating element onto powdered raw material, sintering the raw material as the CandyFab does, except their heating element is a length of nichrome wire instead of a jet of hot air. It gets hot enough to glow, and on the web page they mention that they can work with any powdered material with a melting temperature from 100 to 300 Celsius, including sugar, wax, "Plexi" (plexiglass?), and mixtures such as plastic and sand, plastic and metal powder, powdered paint and sugar powder. Like the CandyFab, each layer of fresh material is laid down on top of the previously worked layer (and I hope that process is automatic as it sounds tedious otherwise) and then you scribble a cross-section on the new layer with the heating element, and then it's time to put down another layer.

The nice thing to this kind of approach is that the unmelted/unfused material provides mechanical support for the built structure. You can build shapes that RepRap and Fab@Home can't make, such as bridges or inverted cones, because any bridge-like part that will go over empty space is built with stuff under it to support it.

This made me curious to start looking around at CNC kits, which could nicely jump-start any fabber project. The XYZ machinery for a fabber is called a "gantry" in CNC language, and there is a very active hobbyist CNC community. Here is a video for a CNC gantry kit that somebody was selling for $195 on eBay. The video itself is for sale ($20) so this is just a teaser.

Here's a few interesting CNC links.

Friday, February 01, 2008

Make Controller Kit

The Make Controller Kit is a pair of boards that snap together, with a AT91SAM7X256 as the microcontroller. For communication it has USB, Ethernet, CAN, and JTAG, and supports the Open Sound Control protocol, which has interfaces for numerous programming and scripting languages. It offers eight analog inputs with 10 bits of precision over a 0-to-3.3-volt range. There are eight high-current digital outputs that can drive relays or two stepper motors or possibly solenoids. There are four servo controllers. It has an 8-position dipswitch. It costs $109 at the on-line store for Make Magazine.

The Make Controller Kit is a pair of boards that snap together, with a AT91SAM7X256 as the microcontroller. For communication it has USB, Ethernet, CAN, and JTAG, and supports the Open Sound Control protocol, which has interfaces for numerous programming and scripting languages. It offers eight analog inputs with 10 bits of precision over a 0-to-3.3-volt range. There are eight high-current digital outputs that can drive relays or two stepper motors or possibly solenoids. There are four servo controllers. It has an 8-position dipswitch. It costs $109 at the on-line store for Make Magazine.

Wednesday, January 30, 2008

CandyFab: The Revolution will be Caramelized

Here's a PDF presentation about the CandyFab, an unusual approach to a hobbyist fabber. These guys decided they could relax their spatial resolution in favor of large volume and cheap fabbing materials. Their fabbing material of choice is sugar, much cheaper than the plastics used by RepRap. Some of the things they make are considerably larger than can be made with RepRap. Here's a Flickr photo set.

Here's a PDF presentation about the CandyFab, an unusual approach to a hobbyist fabber. These guys decided they could relax their spatial resolution in favor of large volume and cheap fabbing materials. Their fabbing material of choice is sugar, much cheaper than the plastics used by RepRap. Some of the things they make are considerably larger than can be made with RepRap. Here's a Flickr photo set.

In September the CandyFabbers came up with a better hot air nozzle that gives them considerably improved spatial resolution, with volume pixels of about 1/16 inch instead of 1/5 inch.

In September the CandyFabbers came up with a better hot air nozzle that gives them considerably improved spatial resolution, with volume pixels of about 1/16 inch instead of 1/5 inch.Some MIT folks have built a fabber that makes stuff out of pasta dough.

Tuesday, January 29, 2008

How does one get started?

The RepRap folks have a page about constructing their version 1.0 fabber, called "Darwin". They recommend that you join the RepRap Research Foundation, which supports new fabber builders, and you can purchase parts from their on-line store.

Fab@Home has a Getting Started page with links to their catalog and the list of materials that you can fab with. A pre-assembled Fab@Home fabber will set you back about $3600 plus shipping, currently with a 6-to-8 week lead time, so I guess people are buying them. The Fab@Home is an impressive thing, and good looking.

Hobbyist fabbers today look the way Linux did in 1993. In five or ten years fabbers will be much more common and much more polished, but the people tinkering today will have 99% of the fun. Linux in 1993 was not at all user friendly, everything needed to be hand-tweaked, and you needed to understand a lot of it to use any of it, and the same was true with cars in 1910, and with fabbers now.

Brilliant RepRap video (thanks to Emeka Okafor)

Bowyer talks about the economics behind the project, particularly its ability to empower communities that are now economically depressed. There is some yummy game-theory stuff in the paper linked here that does not get mentioned in the video, check it out. He also talks about using polylactic acid (wikipedia) as a printing material for the RepRap. This is significant because you can make PLA from starchy vegetables like potatoes and corn, and when you're finished using your PLA object, you can compost it to help grow next year's crop of starchy vegetables. You can have a closed-loop local manufacturing economy that doesn't require trucks or trains or ships to move products around. In fact there are several materials under consideration, and thought has been given to printing a single product from multiple materials. The Fab@Home folks also have an impressive list of materials that can be fabbed, including chocolate.

I got curious about PLA and did a little googling. In a RepRap forum there is a discussion of just how easy it is to turn starchy vegetables into PLA. From the sound of it, it is non-trivial and demands that the person attempting it be quite knowledgeable. One person compares "home PLA production today to home biodesiel production 20 years ago, when it was arcane, a little dangerous, and rare, but theoretically possible" and notes that for many people it will simply not be economical compared to mail-ordering some PLA. I found a place that sells utensils, plates, and cups made from PLA. NatureWorks appears to be a source for PLA in ready-to-work form.